While the U.S. is fortunate to have one of the safest and best food supplies of any country in the world, pathogens and the foodborne illnesses they cause still affect millions of consumers each year. According to the Centers for Disease Control and Prevention, approximately 48 million people in the U.S. fall sick every year, more than 125,000 are hospitalized and roughly 3,000 die due to foodborne illnesses. And it’s important to note that, according to the CDC, unsafe production environments and poor hygiene of food production employees are two leading factors that contribute to foodborne illnesses.

Table of Contents:

- What is the Purpose of Environmental Monitoring in Food Industry?

- Environmental Testing Services

- FSMA & The Role of Environmental Monitoring

- EMPs for the Food Industry

- The Importance of Environmental Monitoring

- Benefits of Having an EMP In Place

- Developing an Environmental Monitoring and Sampling Plan

- Environmental Monitoring Program SOPs

- Sampling Zones

- Environmental Swabbing

- What is the Importance of Doing Environmental Sampling?

- Air & Surface Sampling

- Environmental Monitoring Program Training

What is the Purpose of Environmental Monitoring in the Food Industry?

The purpose of microbiological environmental monitoring is to provide information on the state of a facility. Environmental monitoring should accomplish a few different goals. It should document the quality of the processing environment, and it should assess the environmental quality of nearby clean areas. It should also identify potential pathways of contaminants so that facilities can take preventative measures.

Log10 provides services to aid in pathogen mitigation. Our environmental monitoring testing services are designed to make up an invaluable part of any facility’s environmental monitoring program. Testing services such as environmental swabbing and sampling help facilities determine their baseline levels of organism growth and detect changes that signal the accumulation of dangerous pathogens. Armed with this knowledge, facilities can act swiftly to revise protocols, halt production if necessary and contain and destroy the harmful microbes. Our services benefit a diverse array of food-production environments, from food-processing facilities to pet food and animal feed plants to agricultural and even aquacultural companies.

Below, we will outline in greater detail what these services entail. We will describe how they can be used to keep facilities clean, provide useful data about microbe concentrations and reduce the likelihood of an infectious foodborne disease outbreak.

Environmental Monitoring Testing Services

Essential in the prevention of food-related health issues, costly food recalls and the erosion of consumer confidence and brand reputation, effective environmental microbiological monitoring programs, which include analytical testing services — like those offered by Log10 — are a proven way to collect data on where sources and concentrations of pathogens could enter a food product via a production facility. While an environmental monitoring program on its own doesn’t make food safer, it forms an integral part in monitoring the successful sanitary environment of a food production facility.

Speak to an Environmental Monitoring Test Expert

FSMA & The Role of Environmental Monitoring

The Food Safety Modernization Act (FMSA), enacted in 2011, revolutionized the food industry by shifting focus from responding to foodborne illnesses to preventing their occurrence. Congress enacted the FSMA to recognize that foodborne illness represents a significant public health and economic threat.

Rules, testing and monitoring programs make up a large part of the FSMA. Its rules specify what actions to take at different points in the global supply chain to prevent food from becoming contaminated en route to the end consumers.

Adenosine triphosphate (ATP) testing has been around for more than 20 years. ATP is found in all organic material, so it does not indicate contamination. However, the presence of ATP on surfaces indicates that food residue remains on the surfaces, potentially harboring microorganisms or pathogens. If a high level of ATP is found, facilities should modify their cleaning protocols so that food waste undergoes thorough removal.

Environmental monitoring programs, or EMPs, play a significant role in this regard. Prevention is a key aspect of the FSMA, and a key aspect of prevention is monitoring food-handling areas for signs of pathological contaminants.

Environmental Monitoring Programs for the Food Industry

Pathogens that can cause foodborne illness to occur naturally in the environment and can be introduced into a food facility in a variety of ways, such as raw ingredients, employees, and pests. It is critical to set up and maintain an Environmental Monitoring Program (EMP), as described by the Food Safety Modernization Act (FSMA).

Various harmful microorganisms and pathogens like Listeria monocytogenes, Salmonella spp., and E. coli are known to stubbornly establish themselves in food production environments, and can easily create biofilms that are difficult to remove. Hot environments, such as kitchens and food warmers, provide ideal places for pathogens like Salmonella to breed. Wet areas, such as sinks and dishwashing stations, provide fertile breeding grounds for pathogens such as Listeria.

A continuous and vigilant EMP helps to reduce the risk of microbial contamination. Environmental hand swab results can serve as an early warning sign of and concern for a potential issue to arise. Of course, in the case that a positive indicator test result is received, an EMP can also help quickly and effectively target the areas where corrective action is most needed.

The Importance of Environmental Monitoring

EMPs are vital for protecting against the establishment of environmental niches where bacteria can grow. Once these niche areas become established, bacterial growth areas, or hot spots, and product contamination are almost inevitable. At best, the contamination will reduce the shelf life of the product and cause headaches for the manufacturer. At worst, it will result in pathogen contamination, increasing the risk of foodborne illness for consumers.

Though an EMP cannot make food safer, it can provide vital information about the hygiene and sanitation and practices of a food-processing facility. It can help plant managers keep tabs on their production environment, take note of changes and take corrective action before a serious problem takes root.

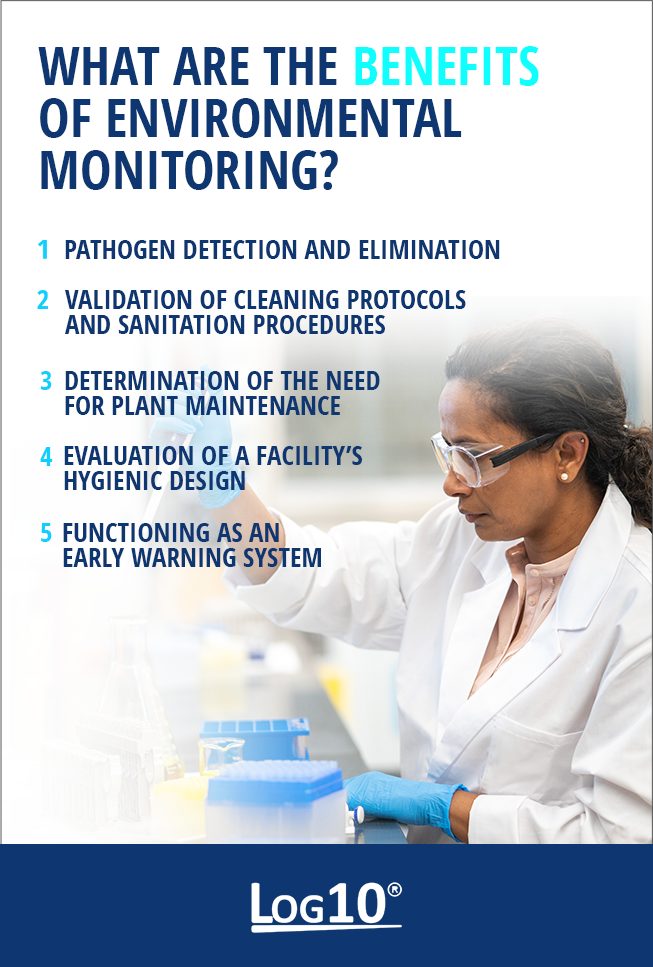

What Are the Benefits of Environmental Monitoring and Testing?

EMPs accomplish several objectives for food-processing facilities:

- Pathogen detection and elimination: EMPs help eliminate niches where pathogens can find ideal growing conditions.

- Validation of cleaning protocols and sanitation procedures: EMPs help verify that facilities are using the correct procedures at the proper frequency.

- Determination of the need for plant maintenance: EMPs can reveal areas in need of preventative maintenance, such as filters that require changing.

- Evaluation of a facility’s hygienic design: EMPs can help a facility evaluate whether its design aids in cleanliness or whether it provides breeding grounds for harmful pathogens.

- Functioning as an early warning system: EMPs provide valuable data to allow facilities to address small issues before they spiral out of control.

Using monitoring systems helps a processing plant generate a daily confirmation that its sanitation processes and cleaning protocols are working effectively. The plant manager or quality assurance manager can preselect several sites to monitor and sample a rotating selection of these sites every day. A system such as this lets a plant know which areas are ripe for contamination. Armed with this knowledge, the plant can take steps to monitor and test these areas carefully.

Developing an Environmental Monitoring and Sampling Plan

Assemble Your EMP Team

One of the first steps to developing an EMP is to assemble an EMP team. This team should include the facility operator or quality assurance personnel and should also include either in-house or outside sources of expertise on microbiology and pathology.

Evaluate Your Current Facility Procedures & Protocols

The next step is to evaluate the facility and its procedures and protocols. Different types of facilities — such as those that deal with animal byproducts, or those with a high concentration of wet surfaces — are likely to require dramatically different EMPs. Tailoring the EMP to a facility’s use and practices is the best way to ensure the success of the EMP and the safety of the food products.

Establish Your Environmental-Bioburden Baseline

Before it can evaluate the facility, the team must establish a baseline bioburden. Doing this can often require lengthy testing to determine the historical levels of indicator organisms and pathogens. Only then will it be possible for microbiological monitoring of the food processing environment to assess what levels of organism activity are anomalous.

Follow FDA Best Practices for Environmental Monitoring Programs

For an effective environmental monitoring program, the Food and Drug Administration (FDA) recommends that a food-processing facility engages in the following practices:

- Perform environmental sampling on both food-contact and non-food-contact surfaces.

- Determine the appropriate pathogens to target, the appropriate test locations and the frequency of sampling. The appropriate target pathogen is likely the most resistant microorganism with public health significance that is likely to be found in the facility.

- Focus environmental monitoring on an indicator organism.

- Establish an action plan in case testing reveals the presence of a significant concentration of indicator organisms or pathogens.

- Document corrective action and follow-up processes for all relevant cases.

Utilize and Follow Your EMP to Minimize Risk & Ensure the Safe Food Products

The EMP should focus on obtaining a representative microbiological sampling of high-risk areas for indicator organisms and/or pathogens. Indicator organisms, though not pathogenic themselves, often act as a warning that conditions are right for a pathogenic outbreak to occur. An effective Environmental Monitoring Program, with appropriately designated sampling areas, can be a very powerful tool in determining the overall effectiveness of cleaning and sanitation procedures. It should be designed to help the facility minimize regulatory, quality and food safety risks. If the EMP reveals positive swab test results showing indicator organisms are present, it can also be an effective aid in narrowing the focus to the most likely potential sources of contamination for immediate corrective actions to be implemented.

Environmental Monitoring Program SOPs

Environmental monitoring program standard operating procedures (SOPs) call for testing for indicator organisms instead of pathogens for a variety of reasons:

- Effectiveness: Indicator organisms are usually present in much higher populations than pathogens are. They can be detected more easily and counted with greater precision.

- Cost: The tests for indicator organisms are less expensive than those for pathogens.

- Efficiency: The results of the tests for indicator organisms also come back more quickly.

- Safety: Since indicator organisms are nonpathogenic, there is no need for hazmat procedures or CDC containment protocols.

Environmental Monitoring Sampling Zones

A thorough EMP designates appropriate environmental samples that are classified according to zones, for a comprehensive view of the cleaning and sanitation procedures’ effectiveness. There are four zones in total, and each is representative of how close that area is to the food product(s) being produced.

Environmental monitoring services sampling zones are categorized as follows:

- Zone 1: Includes all surfaces that come in direct contact with the food product including work tables, utensils, conveyors and mixers.

- Zone 2: Includes nonfood areas of contact that are adjacent or close to Zone 1. These are areas where contamination from the environment are highly likely to have an adverse impact on the safety of the food product. Examples of Zone 2 are maintenance tools, framework of Zone 1 equipment and drip shields.

- Zone 3: Includes nonfood areas of contact that are not close or adjacent to Zone 1. When contamination of Zone 3 occurs, it can be spread to Zones 2 and 1 via movements by employees and machinery. Examples of Zone 3 are drains, floors and walls.

- Zone 4: Includes areas that are located remotely from food production and processing. When Zone 4 is not sanitized properly, it can lead to cross-contamination of other zones. Examples of Zone 4 are maintenance rooms, locker rooms and offices.

A customized EMP provides monitoring of a food production facility to ensure the products are produced in a clean and sanitary environment. Environmental samples are important to collect as the results obtained implicate the effectiveness of sanitation procedures, employee hygiene and overall standard operational procedures. The cost of an EMP is an investment in the protection of a company’s brand reputation and the health of consumers.

Environmental Swabbing

Environmental swabbing uses tools such as Q-tips, sponges, cotton applicators or gauze to swipe organisms from the environment for industrial hygiene monitoring. Swabbing food contact surfaces is a quick and effective way to gather microorganisms. Employees may also use scoops or spatulas during the swab sampling procedure to collect the swabs into sample cups.

Environmental Swabbing Procedure

When employees are sampling the environment, they should be sure to follow basic protocols as part of environmental monitoring SOP:

- Work outward from zone 1 to zone 4.

- Wash hands and use protective gloves.

- Change gloves and sanitize hands between swabs.

- Wipe zone 1 sites with sanitizer after sampling.

- Submit a negative control swab along with the active swabs.

- Transport samples at a temperature of less than 45 degrees Fahrenheit.

- Test the swabs within 48 hours of collection or refrigerate them.

Understanding Environmental Swab Testing & Swabbing Zones

Generally, the swab test method for microbiology swabs zone 1 for indicator organisms only. Facilities test for pathogens only in extreme circumstances. If zone 1 tests positive for a pathogen, production must halt immediately, and the most likely outcome is that products produced in that zone will be recalled. Zones 2 through 4 are typically tested for pathogens.

What is the Importance of Doing Environmental Sampling?

Once a facility knows where its hot spots are, it can use microbiological surface sampling to gather data on the indicator organisms or pathogens found there.

Environmental sampling procedures vary across different facilities, and even across different areas of the same facilities. It’s vital to provide environmental sampling training to employees so they can work safely and effectively. It is also crucial to have the best technology and products available for testing and collecting the samples. Using the right equipment and microbiological testing services for the job leads to increased accuracy, lower costs and heightened plant safety.

For example, ready-to-use swabs result in both lower product costs and labor savings. Using prepared collection devices can eliminate the labor of creating media and filling glass vials. Eliminating glass vials also helps keep plant employees safe because they do not have to expose themselves to the potential hazard of shattering the glass.

Once the swab-sampling procedure is complete, the next step is to test the swabs using a method that has received independent verification of accuracy for environmental samples. The AOAC International (AOAC) Official Methods of Analysis program, for example, validates methods of environmental sampling that meet the correct standards.

In general, environmental samples contain a high concentration of both pathogens and other organisms, which means that the same devices that food-processing facilities use for testing finished products are unsuitable for use for environmental sampling. If the facility uses the wrong instruments, competitor organisms are likely to crowd out the pathogens and indicator organisms and cause the test to produce a false negative.

Air and Surface Sampling

Air and surface sampling are both essential aspects of environmental testing for food-processing plants.

Environmental Monitoring Air Sampling

Microbial air sampling can be a delicate and complex process. Different plants will need to use different sampling strategies and different approaches to data analysis that work for particular circumstances. They should evaluate their microbial aerosol collectors based on the ability of those devices to collect environmental isolates under the conditions at the plant. They should also evaluate the devices based on their ability to collect the microbes without stressing them, which may adversely affect the results.

Microbial air samplers come in a few different types:

Impingers

Most impingers operate by drawing the bioaerosol through a curved glass inlet tube. The air then passes into a liquid medium through a jet. Larger particles collect in the inlet, and employees can remove them by flushing liquid through the tube. Glass impingers are typically considered the best devices for evaluating the bioburden of an environment’s air.

Low shear-force liquid impingers offer the advantage of taking a collection without putting undue stress on the microbes collected. For this reason, they provide reliable results for environments in which plants are trying to capture the most extensive array of environmental organisms possible. They make the best choice when plants are trying to make an initial calculation of the bioburden of organisms in the air. However, using an impinger sampler also comes with a few drawbacks. For instance, an impinger sampler is time-consuming to use, and it requires a higher degree of expertise to operate than other devices. It is also not as portable as other options. For these reasons, impinger samplers are not often plants’ first choice for routine air sampling.

Impactors

An impactor is a jet that has an agar sampling surface underneath it. The jet directs particles toward the agar surface so that they impact upon it. Larger particles impact the surface first, followed by smaller ones.

Two main types of impactors are stacked sieve samplers and slit-to-agar samplers.

Stacked Sieve Samplers

Sieve samplers can provide data about particle size distribution for air samples. A stacked sieve sampler consists of six parts, each one a plate containing 200 holes. Within the stack of plates, each lower plate has smaller holes. At the bottom of the stack sits a Petri dish containing an agar solution. As particles come into contact with the plates, larger particles impact the higher plates, whereas smaller particles impact the lower plates.

Slit-to-Agar Samplers

Slit-to-agar samplers give no information about particle size. They are useful when plants need to identify the components of the bioaerosol over time and under different types of activity. Slit-to-agar samplers work by drawing air through a narrow slit. From there, they direct the air toward a Petri dish containing agar. The collection surface sits on a rotating turntable, and when microorganisms impact the agar surface, they are separated spatially by the plate’s rotation.

Gravitational Samplers

Settling plates — for example, Petri dishes that contain agar solutions — are the simplest form of gravitational samplers. They collect particles that settle into them because of the force of gravity. They can be imprecise: They are likely to attract larger particles because of the rapid settling rate of these larger particles. They offer a particular benefit, though. Where bioparticles are large, settling plates offer clues as to the point of their emission. They use gravity and the physics of particle to dynamics to provide data about the contamination gradient in the air.

Centrifugal Samplers

Though they cannot generate data about particle size or origin, centrifugal samplers are exceptionally well suited for taking a large number of samples quickly and easily. They work by creating a vortex in which particles impact upon the inner wall of a rotating drum, which contains an agar collection surface. The drum is typically small and portable, usually light enough to be handheld, so centrifugal samplers are easy for many facilities to use.

Environmental Monitoring Surface Sampling

Microbiological surface sampling is crucial for any food-processing facility’s quality control. As with air testing, many different techniques and devices exist for various aspects of environmental surface testing. The main factors that determine the choice of surface sampling equipment are these:

- Surface geometry: This factor includes whether the surface is curved, flat, grainy, smooth, etc.

- Chemical condition: This factor includes whether the surface is has come into contact with oils, salts, disinfectants or other chemical residues.

- Contaminant types of and concentration: The type and number of microbial contaminants expected, along with their predicted survival rates, also help determine the choice of surface sampling equipment.

Four different types of contact surface sampling equipment are most commonly used:

Contact Plates

Contact plates enjoy widespread use for surface sampling. This type of sampling works best on smooth, flat surfaces. To perform contact sampling, employees typically place solidified nutrient agar against part of the surface for about five seconds. They then incubate the samplers and take a microbial count. For curved or uneven surfaces, flexible slides may be suitable. In other cases, employees may use sterile velvet pads or Cellophane tape to make an imprint of the surface and then make a second agar imprint.

Swabs and Wipes

Along with contact plates, swabs and wipes provide one of the most common ways to sample environmental surfaces. Employees typically use one of two techniques. The first is to use a sterile cotton-tipped applicator or gauze pad to swab the surface, then swipe the swab across an agar surface or immerse it in solution to remove the microbes. The second technique is to use calcium alginate swabs to wipe the surface. The swabs are then dissolved in solution to remove the microbes. This latter technique has been shown to recover more organisms than cotton or gauze swabs alone. However, calcium alginate can inhibit microorganism growth, so facilities must use it with care.

Direct Surface Agar Plating

The technique of direct surface agar plating is less common. It is time- and labor-intensive but has applications in situations where the geometry of the surface makes the techniques above unsuitable. It is also sometimes used when the whole surface, instead of random areas, must undergo testing.

Rinsing and Vacuum Collection

This technique is also less commonly used. It requires auxiliary equipment such as a vacuum pump and an airflow measurement device.

Sampling Specifics

Environmental Monitoring Sampling Locations

The following are some surface areas that facilities should sample in each zone:

- Zone 1: Tables, countertops, utensils, mixers, slicers, bins, buckets

- Zone 2: Equipment, hoods, drip shields, control panels, pipes, computer screens, maintenance tools

- Zone 3: Floors, walls, ceilings, HVAC systems, drains, foot mats, forklifts, brooms, mops, pallets

- Zone 4: Hallways, offices, meeting rooms, locker rooms, break rooms, restrooms, loading docks, maintenance shops

Environmental Monitoring Sampling Frequency

Additionally, different zones should be tested with different frequencies and with varying numbers of samples per testing:

- Zone 1: Weekly sampling, after cleaning but before the application of sanitizer. The number of required samples depends on the environment.

- Zone 2: Weekly sampling. Ten to fifteen samples per week.

- Zone 3: Weekly sampling. Ten to fifteen samples per week.

- Zone 4: Monthly sampling. Five to ten samples per month.

Environmental Monitoring Program Training

FSMA Preventive Controls for Human Food rules require ready-to-eat food producers to implement and manage an environmental monitoring program for routine monitoring of their environment to reduce risk and contamination. Our environmental monitoring program training will help you understand the important aspects of an EMP, including sampling and zones, data management and advanced investigation. We’re also able to offer consultation support when creating an EMP for your business.

Contact Log10 for Microbiological Environmental Monitoring Assistance

Log10 is an ISO 17025 accredited testing facility that provides reliable and timely EMP data to facilities making the establishment of an early warning system for microbial hazards, the taking of remedial action and the resulting reduction of foodborne contamination highly attainable for every food production facility. To learn more about how we can help you, contact us to speak to an expert on environmental monitoring!